By Adrian Arima –

How long have humans brewed beer? Patrick McGovern, the world’s foremost historian of ancient brews, hints in Ancient Brews (2017) that this activity has been around possibly at least for 11,000 years based on vessels from Gobekli Tepe in Anatolia (Turkey). How sophisticated was brewing in antiquity? Since the ancient artifact ca. 100 CE known as the “Baghdad Battery” was discovered in the 1930’s, the purpose for which it was used has been a mystery. Wilhelm Koenig, a German curator of the Baghdad Museum, discovered it near Ctesiphon – the Sassanid capital and previously in the Parthian Empire around 1936 but the context is uncertain according to Dr. St. John Simpson of the British Museum. While some have proposed its use as a galvanic battery or device for electroplating, debate has been fierce.

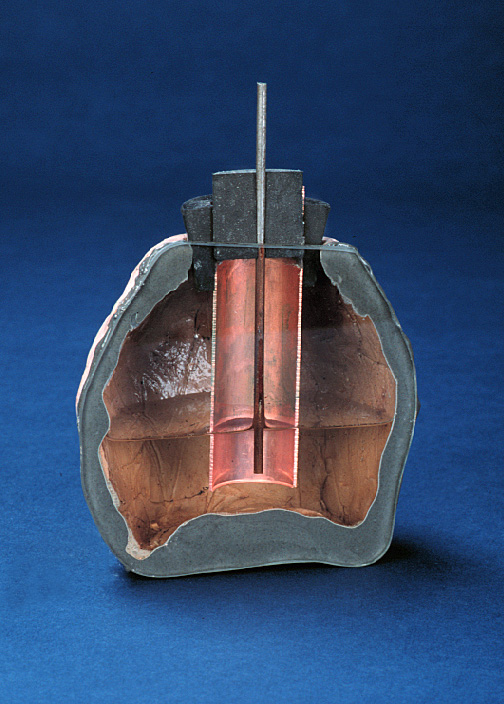

This artifact consisted of a ceramic jar along with a copper tube and iron rod, suspended inside from a bitumen seal around an opening at the top. There were traces of an acidic substance inside the jar. The most popular theory is that the purpose of the Artifact was to generate an electric current using an acidic electrolytic solution such as vinegar or fruit juice. As mentioned, a few proposed uses included electroplating metals, electrifying religious idols so as to impart a “magical” shock when touched, or even for therapeutic pain relief. It has even been suggested that the artifact was used to store and preserve scrolls since the Artifact jar was similar to jars found to contain scrolls, although if an electrolytic liquid had been also stored internally, this would defeat any document storage purpose.

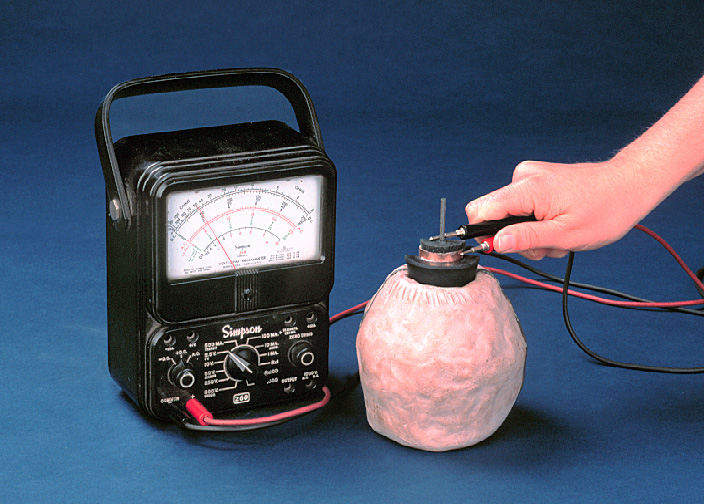

While it is clear that this Artifact could be used to generate an electric current, the voltage would be very weak, probably less than one volt with the natural acids available at the time (such as vinegar). This would not be enough for any practical applications unless several batteries were wired up in series, which presumes an advanced understanding of electric currents by ancient Mesopotamians. Additionally, no battery accessories such as wires were found. Other criticisms of the battery theory include the fact that no electroplated artifacts have been found, the lack of any documentation of battery-type uses, the fact that a bitumen seal would be inconsistent with the need to constantly replenish the weak electrolytes in order to sustain the battery function, and that there did not appear to be evidence of connections on the bitumen top to the metal nodes inside the jar. Advocates for its use as an “electrical” device of some sort include Willard Gray, W. Jansen, Arne Eggebrecht and even as experimented by the Mythbusters documentary program in 2005. Detractors of its potential use as a “battery” for galvanic storage include Paul Craddock of the British Museum Research Laboratory and Professor Elizabeth Stone of the State University of New York, Stony Brook, among others.

The scroll-container theory does not explain why all the parts (copper tube, iron rod) are needed, and the small size (about 5 inches high) does not seem practical as a container for scrolls. There is no evidence that the copper tube itself was a copper scroll (such as was found among the Dead Sea Scrolls). It has been hypothesized that copper was inserted into the container because of its anti-microbial properties, and that the acidic remains were from decayed papyrus, but this does not explain the iron rod or why the rod was separated from the copper tube.

It thus seems appropriate to explore other possible uses of the Artifact, which do not assume its purpose was to generate electricity for whatever purpose or to store scrolls.

One hypothesis to consider is that the Artifact may have been used to purify beer (or possibly another acidic beverage). A search of the internet reveals (a) that one byproduct of fermentation is hydrogen sulfide (H2S) which causes an off-taste in most kinds of beer; and (b) copper is commonly used today to remove H2S from beer. See, for example, US Patent No. 3,544,329A, Electrolysis of Fermented Beverages, filed in August 1967, describing the removal of H2S by charged copper plates. The patent describes the problem as follows:

“This invention relates to a method and means for the improvement of the flavour of fermented beverages, such as beers, ciders, and wines, by elimination of hydrogen sulphide produced during fermentation.”

Hydrogen sulphide is a normal product of yeast metabolism; during fermentation of beverages such as beer it is produced from cysteine by desulphuration and from inorganic sulphate by reduction, and probably from other precursors as well. It is well known to brewers that beer, and particularly newly fermented beer, for this reason often contains so much hydrogen sulphide as seriously to impair its flavour, and especially its aroma.

Copper in solution reacts to H2S to produce copper sulfide which either precipitates out or is removed by a normal beer filtration step. Contamination of beer by H2S has become more of a problem in modern beer production as brewers shifted from copper vats to stainless steel:

In breweries, the preferred use of stainless steel rather than copper has occasionally led to increases in hydrogen sulfide (H(2)S) concentrations in beer since its elimination as copper sulfide (CuS) did not take place. Depending on the character of the underlying beer, this off-flavor can become quite noticeable. The advanced version of a copper electrolysis system eliminates this flavor defect. [1]

Similarly, copper has been used in processing wine to remove H2S: Some home winemakers rack their stinky wine through a clean piece of copper screen, or they place a few copper pennies in the wine container. Copper converts the hydrogen sulfide gas into a solid material called copper sulfide. Copper sulfide is not soluble in wine, and it settles to the bottom of the tank. After a few days, the winemaker racks [decants] or filters the wine off the copper sulfide residue. But, placing copper metal in wine can cause other problems. Wine has a low pH, and the acid may dissolve too much copper. [2] (Note that this process takes “a few days” – a factor discussed below in relation to the Artifact.)

Beer has certainly been brewed in Mesopotamia as early as 3500 BCE, although some postulate the earliest brewing may be Neolithic or even earlier and that grain growing itself may have been influenced by the desire to brew beer as far back as 13,000 BP, generally agreeing with McGovern. [3]. As explained by Bertman, the ancient Mesopotamians also had substantial technical expertise and experience in chemical processes, in particular for brewing beer:

. . . the Mesopotamians also made progress in chemistry, judging by ancient artifacts that have been unearthed: crucibles and pieces of apparatus for filtering, distilling and extracting various chemical substances. Their scientific and technical know-how is also demonstrated by the products which they manufactured, including soap, tanned leather, dyed wool, glazes and glass, which would have required a familiarity with the properties of acids, lime, sodas and silicates. A sophisticated understanding of fermentation was also a prerequisite for the manufacture of Mesopotamia’s most popular drink, beer, of which seventy varieties existed. The ca. 1800 BCE Hymn to Ninkasi, the goddess of brewing extols her gift of beer to humankind.

Perhaps the single most intriguing artifact ever unearthed in Iraq is the “Baghdad battery.” . . . . The most convincing theory to date is that the object functioned as a primitive electric cell, or battery. [4]

Any hypothesis on a potential use of the Artifact would have to explain the function of all the four key elements of the Artifact: 1/ Presence of an acidic solution or material. 2/ Use of both iron and copper nodes, not touching each other. 3/ Top is sealed (with bitumen). 4/ Size and shape: a tapered jar approximately 5 inches high. This assumes the jar itself is made of any material that is generally inert with respect to the reactions inside, and that the function of the jar is to contain the reaction in a closed environment.

Finished beer is an acidic solution – ales and lagers having a pH of about 3.8 to 4.5 [5]. Vinegar (dilute acetic acid) has a pH of about 3. [6] Lemon juice (vitamin C= ascorbic acid) has a pH of about 2.25 and orange juice about 3.8. [7] Most wines fall between 3.0 and 3.6. [8] (Anything below pH 7 is acidic.) So if the Artifact had contained beer, that would provide an explanation for the traces of acid found in it.

Iron has a negative oxidation potential which means that in an acidic solution, iron will give up electrons to the acid resulting in hydrogen molecules (H2) going into solution. Copper has a positive oxidation potential, so it does not cause this kind of reaction. But copper in contact with the solution can use the electrons that were captured in the H2 by the iron reaction so that the copper can more easily go into solution and interact with H2S. This occurs if the copper and iron nodes are not connected. If they are connected, the electrons transfer between metals through the connection. This may explain why both iron and copper are used in the Artifact and why they are not connected. This system would probably need a time frame of days (rather than minutes or hours) to work. (See citation above, of de-sulfuring wine with copper over “a few days.”) Sealing the system with bitumen would help contain the H2 gas. It would also keep out oxygen, which otherwise would reduce efficiency. A less secure closure, such as a stopper, would not function well as a seal against H2 leakage out – and O2 leakage in – over the required time period of days.

What explains the small size of the Artifact? It may have been just a model or prototype and larger versions would have been less likely to have survived without damage. If broken apart, the fragments of a larger model may not be recognized today as being the “battery.” It may also be that the Artifact was only a curiosity or that its cost (copper likely being an expensive item) or performance did not justify it being incorporated in regular beer production. Perhaps it was only an enhancement for diehard beer aficionados.

Another explanation for the Artifact’s small size is so it can be easily shaken. Shaking of the system would be beneficial because hydrogen gas on the iron rod would reduce the surface area for the reaction and secondly, shaking the system would allow for better homogenization and exposure of the copper to the dissolved gas. Indeed, the size and shape of the Artifact is strikingly similar in size and shape to small cocktail shakers used by bartenders today. [9] Perhaps the ancient Mesopotamians, like James Bond, preferred their drinks “shaken, rather than stirred.”

What could have led the ancient Mesopotamians to process beer this way? One possibility is that some beer accidentally left in a copper cup could have improved the taste, leading brewers to experiment with different metals, combination of metals and conditions to optimize the process. It also is possible that Mesopotamian beer brewing trends or R&D shifted to processes and yeasts that resulted in less H2S by-product, thus reducing the need for the Artifact. This could explain why so few of these Artifacts have been uncovered.

The passage from Bertman [4 above] suggests the Artifact may have been buried with its inventor so he could practice his electrical engineering craft in the afterlife. But it also would be consistent with burial practices where food containers & utensils are buried with the dead to ensure their family member’s sustenance in the afterlife. In this case, the deceased beer lover would not have been placed in an afterlife deprived of his purified beverage, which he may have considered a form of “hell” if beer was absent!

It is hoped that the above hypothesis will stimulate further thinking about potential uses of the Artifact and perhaps some real-life experimentation on whether a modern-day mockup of the Artifact could indeed be used to enhance the flavor of rudimentary beers or wines.

—————————————————————————————-

The author is indebted to Thorsten Kirschberg, Ph.D., who provided the description of the chemical processes involved.

Notes

1 Patrick McGovern. Ancient Brews: Rediscovered and Recreated, Norton, 2017, 39: E. Pfisterer et al. “Control of Hydrogen Sulfide in Beer with a Copper Electrolysis System. Master Brewers Association of America Technical Quarterly 41.1 (2004) 52.

2. http://www.thevintnervault.com/index.php?p=w_m_tips&id=5781

3. Joshua Mark, “Beer in the Ancient World” Ancient History Encyclopedia, March 2, 2011. Also see Melissa De Witte, “New Evidence Supports the Hypothesis That Beer May Have Been the Motivation to Cultivate Cereals”, Stanford Report Sept. 12, 2018 on work of Li Liu et al. “Fermented beverage and food storage in 13,000 y-old stone mortars at Raqefet Cave, Israel: Investigating Natufian ritual feasting” Journal of Archaeological Science Reports, 2018.

4. Stephen Bertman. The Genesis of Science: The Story of Greek Imagination, Prometheus Books, 2010, 35.

5. https://discussions.probrewer.com/showthread.php?15898-pH-of-finished-beer

6. https://www.finecooking.com/article/the-science-of-vinegar

7. A. Reddy et al. “The pH of Beverages in the United States” Journal of the American Dental Association, 2016.

8. http://winemakersacademy.com/importance-ph-wine-making/

9. https://www.barproducts.com/3-piece-cocktail-shakers-stainless-steel-deluxe

(6″ high)